The Encyclopaedia: G-L

| Gable: | Vertical, triangular termination to a roof. |

|---|---|

| Gainsborough Old Hall Lincolnshire: | Medieval complex containing a wealth of fascinating fifteenth-century carpentry. The hall and its arch-braced roof, tree-ring dated to 1452-85, is probably the most impressive part, but the whole range with its creaky floors is worthy of exploration - with a medieval kitchen to boot. |

| de Galmeton, Robert: | English carpenter (fl. 1312-26). Master carpenter at Exeter Cathedral from 1313-22 and 1326. The years 1313-16 find Robert repeatedly being paid for making centerings (cinternas), bulky temporary structures carpentered to expedite the construction of masonry arches. His versatility as a craftsman is evident as in 1317 Robert was paid £4.00 for making that paragon of the medieval carpenters' art, Exeter's highly ornate and technically ambitious Bishop's throne (Erskine, 73-75, 85). The mason Thomas of Witney is often credited with the design of the throne, but no conclusive evidence exists for this assertion, and there is no reason why a carpenter could not have designed this masterpiece (see illustration below). |

| Girt or Girding Beam: | See summer. |

|---|---|

| Goldyng, John: | (fl. 1426-51) Carpenter, King's Carpenter 1426-51 for Henry VI.

Literature: Harvey (1984).

|

| Graveley, Edmund: | (fl. 1444-84) Carpenter, King's Carpenter to Edward IV and Richard III from 1461 onwards. As King's Carpenter,

he was probably responsible for the riotously ornamental hammer-beam in the hall of Eltham Palace,

carpentered for Edward c. 1479.

Literature: Harvey (1984).

|

| Great Coxwell Barn: | A must on the itinerary of any connoisseur of English medieval carpentry.

William Morris thought the late thirteenth-century monastic barn 'the greatest piece of architecture in England ... unapproachable in its dignity'.

Pay a visit to see why. Illustrated under 'Aisled Construction'.

Literature: Horn & Born (1965).

|

| Great Cressingham Norfolk: | A fine and intriguing hammer-beam here in the nave of St Michael's, dating probably to around 1430.

Ostensibly the roof is a standard example of the collarless Norfolk roofs - albeit with some idiosyncratic figure carving. Yet with scrutiny

you discover the work of a cunning carpenter with a penchant for illusion and indifferent to increased labour - provided there was an ornamental payback.

For instance, the hammer post construction appears to the conventional arrangement of two discrete timbers: a hammer post and an arch-brace to

principal, and this was the way the carpenter intended it to be apprehended. Yet in reality, the hammer post and arch brace are one timber.

To perpetrate the ruse, the carpenter worked a vertical roll moulding at the interface of the 'two' timbers.

Take your binoculars and you'll spot more illusory framing in this bravura display of carpentry. The carving is a joy.

Literature: Beech (2015).

|

| Great Malvern Priory, Worcs: | Great Hall, demolished 1841. Awaiting further details

Literature: Parker, Vol II (1882); Wood (1983).

|

|---|---|

| Greensted Church Essex: | Awaiting entry |

| Grundisburgh Church Suffolk: | The nave of St Mary’s is sheltered by a superb double hammer-beam stuffed with angels. I’ll deal with the structure in three tiers: fairly conventional lower hammer-beam framing (although the hammer posts are set well back from the hammer-beam ends) rises to the second tier of hammer beams which are framed into pendant hammer-posts. This second tier of hammer-beam framing must, then, be ornamental. The pendant posts are arch braced to slightly cambered collars. Upon the collars stand short king posts. Ornament is exuberant and extensive: the pendant hammer posts terminate in complex part-floral part-architectural drop finials. Angels adorn the wall posts, the lower hammer beams, and the king posts of the upper framing – the latter an unusual refinement. When painted, the roof must have been a glorious portrayal of the intended destination of the faithful below. Grundisburgh is also a composition of subtle sophistication. To the gable above the chancel arch, the double hammer-beam framing supplies a sharply cusped cinquefoil, a motif intrinsic to fifteenth-century ‘Perpendicular’ architecture and art. It would have served well to frame both the rood and any blood-curdling Doom painted thereon. Also, the receding forms created by the arch-braces of one truss, and the collar of the subsequent truss, are such that each king-post angel appears to reside in its own, individual, domical niche. The roof is vaguely dated by all secondary sources to the fifteenth century. To note: the roof was restored in the 1880s and some of the heads and wings of the angels were replaced. |

| The Guesten Hall: | The roof of a building formerly in the precincts of Worcester Cathedral is an early example (c. 1320) of an

arch-braced collar roof. Unlike later roofs of this type, at this stage the carpenter did not think to incorporate wall posts to which the principals

could be braced to aid stability. Also notable is the cusped wind-bracing which was to become a common feature of medieval display roofs in the

west Midlands.

Now re-erected at the Avoncroft Museum, Bromsgrove.

Literature: Dollman & Jobbins (1861); Wood (1983); Charles (1995).

|

|---|---|

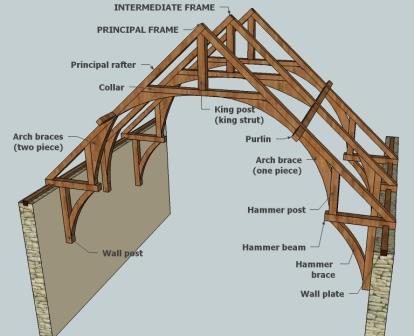

| Hammer Beam: | Horizontal transverse timber projecting from the inner face of the wall plate, supports hammer post. Often elaborately carved, or having fixed, applied carving (see below). |

| Hammer-beam Roof: | One of the great technical and artistic achievements of the English medieval carpenter: a system of using opposing

brackets to manage the span, and thus the thrusts, of an untied roof.

In the fifteenth century, rather than structural, the intent behind such carpentry became increasingly ornamental. Hammer-beam carpentry seems to have developed from two distinct structural nodes. In the early fourteenth century, aisled construction was the source (see Fig. a) - the hammer-beam brackets replacing arcade posts. Very few of examples of this type of construction are known. Following the completion of Hugh Herland’s Westminster Hall (c. 1398), there was an explosion in hammer-beam roof construction, thenceforth based on principal rafter carpentry. Notable examples of hammer-beam roofs are: Pilgrims’ Hall, Winchester, an adaption of aisled construction (c. 1310); Westminster Hall (begun 1393); St Mary’s, Bury St Edmunds (c. 1430); the nave and north aisle of Wymondham Abbey (mid to late fifteenth-century); (see illustrations and Fig. b below). Double hammer-beam roof: roof with two tiers of hammer beams. Often - but not always - the upper tier is non-structural. Notable examples include Bacton Church; St Mary at Quay, Ipswich; Tostock Church; Woolpit Church - all Suffolk; Tilney All Saints Church, Norfolk. Curiously, with a few exceptions, medieval double hammer-beams are primarily Suffolk phenomena.

Literature: Beech (2015).

|

Left: Pilgrims’ Hall, Winchester, (c. 1310). Right: north aisle of Wymondham Abbey, Norfolk (probably late fifteenth-century).

| Hammer Beam Angel: | Discrete carved figure applied (usually morticed) to the end of a hammer beam. One of many examples in East Anglia: Tilney All Saints Church, Norf., illustrated below. (cf. ‘Recumbent-figure hammer beam’). |

|---|

Tilney All Saints Church, Norfolk, probably third quarter of the fifteenth century.

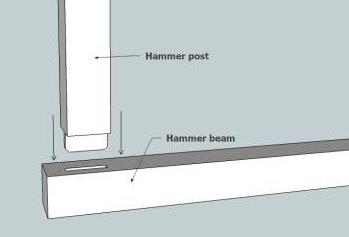

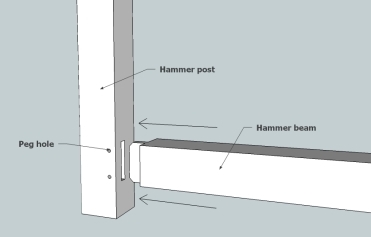

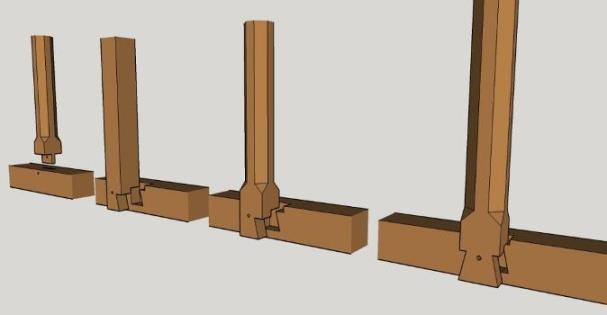

| Hammer Post: | Vertical timber, rising from the end of the hammer beam (see Fig. b).

Pendant Hammer Post: Belonging mainly to the second half of the fifteenth century and later, the pendant post is structural adaption in pursuit of ornamental objectives. Construction: In conventional hammer-beam construction the hammer post is tenoned vertically into the hammer beam. In pendant construction the hammer beam is tenoned horizontally into the hammer post. |

|---|

| It is carpentry of negative structural implications. Pendant construction means that on square timbers with a section of, for example, 8in (210mm), any shearing force the beam is meant to carry rests on a 1½in (40mm) tenon rather than its full 8in width as in conventional construction. Also, under certain lateral wind-loading conditions the mortice and tenon joint may undergo leverage and go into tension (conventionally it sat happily in compression). Any forces, then, that this triangulation (with the principal rafter) is meant to control depends merely on the one-inch (25mm) pegs locating the joint and the poor resistance to shear of the short-grain tenon. Carpenters, though, persevered with this suspect construction, the pendant post favoured even in the regal setting of Eltham Palace (c. 1475-79). Why?

Pendant-post carpentry allows greater scope for ornament. One of the ornamental motifs of fifteenth-century carpentry was the ornamental wooden 'boss', and ornate bosses, often foliate in nature, became a common feature of East Anglian roofs. These were frequently mounted at the intersection of the purlin with the principle and intermediate rafters, and on the underside of king pendants. The nave of Wymondham Abbey contains some particularly extravagant examples of wooden bosses. Pendant-post carpentry allowed the carpenter to move similar ornament at a lower, more visually dominant level in the form of what would later be known as the 'drop finial.' Eltham Palace and Gestingthorpe Church, Essex, are examples of this technique. If that seems glib, then another ornamental concern may have been the catalyst: the pendant post provides a location for devotional imagery. On some pendant hammer posts the carpenter created a niche, and in that space he would carve a saint. Suffolk churches at Tostock and Wetherden hold particularly fine examples of this artistry. Such holy figures are common denizens of the wall posts of East Anglian roofs, but pendant-post construction supplied extra, more conspicuous locations for these devotional figures, and so would (hopefully) stir saintly thoughts in the congregation below. Interestingly, it seems that medieval pendant-post hammer-beam roofs are confined mainly to south-central East Anglia. A minor industry in their production existed in the trilateral area formed by connecting the towns of Ipswich, Bury St Edmunds and Gestingthorpe. You can find them in churches at Wetherden, Cotton, Earl Stonham; Grundisburgh; Tostock (all Suffolk) and Gestingthorpe (Essex). This list is not comprehensive. Tostock displays an astonishing structural modification of the construction, again in the service of devotional ornament. Literature: Cescinsky and Gribble (1922); Cautley (1982); Beech (2014; 2015). For the effect of wind forces on roof structures, see Yeomans (2009); Sobon & Schroeder, (1984) |

| Herland, Hugh: | (c. 1330 - c. 1406). Arguably the greatest English medieval carpenter. From boyhood Hugh Herland was steeped in the mystery of carpentry. From the sparse documentary evidence it seems likely his father was a carpenter, and probably his grandfather before him. Early in his career, Hugh's probable father, William Herland (d. 1375), worked under the King's Carpenter William Hurley (d. 1354). Hurley carpentered the fabulous roof of St Stephen’s Chapel, Westminster (completed c. 1348), for Edward III, and was probably the 'subtle craftsman' who 'wrought and cunningly framed' the carpentered tour de force of the vaulting and lantern over the crossing at Ely Cathedral (completed c. 1338). William Herland succeeded Hurley as the England's pre-eminent carpenter, going on to design, construct, and supervise a wide variety of royal works, from ecclesiastical stall-work to bridges and major roof structures. So from a small boy Hugh was surrounded by carpentry, carpenters, and their tools and designs. And he was instructed, not in some village carpenter's yard knocking together hovels and handcarts, but in an elite atelier designing and framing state-of-the-art works for the Crown. Throughout his career Hugh exploited this privileged grounding. He became a craftsman of versatility and virtuosity, making and designing a range of items from choir stalls and tomb canopies of the most delicate tracery, to siege engines and monumental roofs. When we first encounter Hugh in contemporary records he is already thirty years old and working in a supervisory capacity with his father, William, on construction works for Edward III at the Royal Palace at Westminster and the Tower of London. In 1367, it is possible he was responsible for the design and execution of the wooden tester over the tomb of Queen Phillipa of Hainault (wife of Edward III) in Westminster Abbey. The next year finds him in Kent, in the role of military engineer, working on Edward's revolutionary new castle at Queenborough (destroyed) on the Isle of Sheppey, and on repair works at Rochester Castle. During this period he was paid 8d. a day for making springalds - catapults for shooting giant arrows. At the death of his father in 1375, Hugh was appointed King's Carpenter - the 'disposer of the King's works touching the art or mystery of carpentry', a position he held until his death. In that same year he was engaged in run-of-the-mill carpenters’ work - building a roof - that of the Abbott's Hall in the precincts of Westminster Abbey (illustrated below). By contrast, two years later he designed 'one of the finest compositions in gothic art': the tester of the tomb of Edward III. A vaulted structure adorned with filigreed tracery, scholars have considered it 'the very highest point in the design of decorative woodwork.' Later, in the timber vaults of the Collegiate Church at Arundel (c. 1380-90), and Winchester College Chapel (1387-94) (illustrated below) Herland developed these delicate forms and adapted them to an architectural scale. Between 1389 and 1397 Herland spent much time in Winchester, working on projects for the king at Winchester Castle, and on Bishop William Wykeham's new Winchester College. Away from Hampshire, in 1397 Herland may have designed the splendid waggon roof over the Chapter House of Canterbury Cathedral. In 1398 he was appointed to supervise the construction of a new harbour at Great Yarmouth. Also in the final decade of the fourteenth century, Herland completed his masterpiece: the monumental and technically audacious hammer-beam roof of Westminster Hall. It was the culmination of both his engineering nous and aesthetic sensibility, and is surely the unsurpassed apogee of medieval carpentry. Literature: Harvey (1984); Beech (2016, 2015)

(See my own reconstruction of a key part of the Westminster roof here.)

|

|---|

Left: the Abbott's Hall, Westminster (c. 1375); right: the timber vault of Winchester College Chapel (1387-94).

| Hewing: |

An axe I have, by my crowne

As sharpe as any in all thys towne … Here is a good hackestocke On this you may hewe and knocke Shall none be idle in this flocke Noye’s Fludde, recorded early C15 When a medieval artist wanted to represent a carpenter at work, he almost always depicted him hewing. Such bias shows just what an elemental and quotidian activity hewing was for the medieval carpenter. Hewing is a stage in the conversion process, a method of removing bark and sapwood to provide a flat face / faces. In the case of main framing timbers, logs would generally be hewn to a square section to produce 'box-hearted' timbers. Alternatively, in the case of secondary timbers - common rafters for example - just two flat faces might be hewn. Hewing is hard work and the carpenter hewed only to the extent necessary to render the timber suitable for its purpose. The purpose of hewing was not to produce a straight timber. Crooked timbers were also hewn. Hewing happens in two stages. Firstly, after being marked out and secured, large logs are 'scored': a series of vertical notches are cut along the length of the timber with a conventional long-handled axe. Scoring allows the waste to be split away more easily during the second stage of the process: 'broking' or 'facing.' Now the hewer changes position and chops vertically down along the grain with a different, more specialised tool, the 'broad' or 'side' axe. At this stage, a conventional axe might glance off the timber or dig excessively into the grain, but the smaller side axe is more controllable and is bevelled on one side only and so cuts a flatter face. The handle hopefully will be cranked, to avoid bashing the knuckles. Broadaxes and side axes generally have a thinner and, as its name implies, broader blade. These refinements again aid the creation of a flat surface. A skilled craftsmen with a keenly-honed side axe can produce an exceptionally even and smooth surface, and hewn, in contrast to planed, timber has a character all of its own. (If there is some confusion here about the difference between a 'broad' and a 'side' axe: a broadaxe is always broad and might be bevelled on one side only; a side axe - a more modern term - is always bevelled on one side only - but might not be so broad. Hope that clears it up...). Literature: Edlin (1948); Binding (2004).

|

|---|

Top: the author 'scoring' or notching a log. Below: a modern side axe; note profile of blade, right.

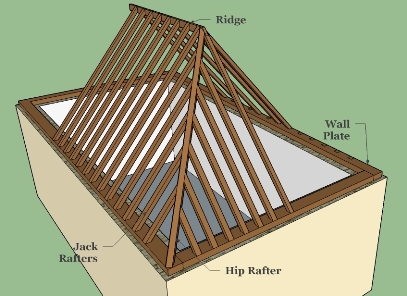

| Hip Rafter: | Rafter framed to facilitate the two slopes of a hipped roof (a roof without vertical gables), into which shortened common rafters, known as jack rafters, are framed. |

|---|

| Hurley, William: | (fl. 1319-54) English carpenter; the King's Carpenter, probably from 1332 and certainly

to his death in 1354. Like his contemporary carpenters, Hurley was skilled as an engineer and as a carpenter of works of

considerable aesthetic refinement. He was master carpenter for the completion of St Stephen's Chapel, Westminster, during the

1340s and 50s.

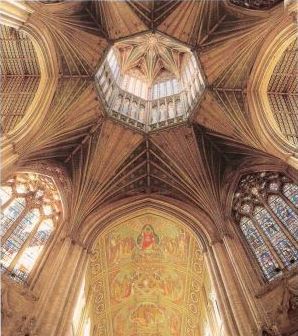

Edward I commissioned St Stephen's, a new family chapel for his royal palace at Westminster, in 1292. His intention was to rival the splendour of his cousin Louis IX's personal chapel in the Royal Palace in Paris, Sainte-Chappelle (begun 1240). The construction of St Stephen's, however, had got off to a faltering start, only regaining momentum in the reign of Edward III. By 1348, the masonry shell and roof were complete, and Edward commissioned a fabulous interior, decorated with polychrome walls and fittings, and large stained glass windows. Profligate sums were lavished on materials - gold, azure and vermilion - to embellish the entire space. After recent victories at Crecy and Calais, this 'most splendid chapel in England' was to be a triumphal work of a king at the zenith of his reputation. And, to complete a structure that soared nearly a hundred feet (30.48m) high, the chapel was topped, not by a masonry vault, but by a carpentered vault 'with timbers which cannot be counted owing to the number of pieces.' The vault, now lost and its form unknown, was installed by Hurley, and Hurley also worked on the sumptuous stallwork in the chapel. Hurley, then, was capable of craftsmanship of the utmost refinement. As an engineer, Hurley's credentials had already been well established a decade or so before in East Anglia. In 1322 the central tower over the crossing of Ely Cathedral collapsed, taking much of the masonry of the four central piers with it and leaving an enormous void. The man entrusted with the care of the fabric of the cathedral, the Sacrist Alan of Walsingham, 'knew not which way to turn himself or what to do for the reparation of such a ruin.' The solution, the multi-ribbed vault and lantern (completed c. 1339, illustrated below), 'designed with great and astonishing subtlety', were the product of William Hurley's, genius. This work, 'cunningly framed' by 'subtle craftsmen', is no flimsy structure suggesting a compromise when faced with the unfeasibility of a more monumental masonry counterpart. The timbers of the octagon and lantern have a self-weight estimated at 450 tons. At 62ft (18.89m), the massive unseen timbers propping up the lantern are the longest known in any British medieval building. Trees of adequate size to provide the timbers were scarce, documented as being 'sought far and wide, found with much difficulty, bought at a great price.' The vast octagonal space of around 70ft (21.34m) in span remained the widest central void bridged by any craftsman in any English building until Wren constructed the dome at St Paul's over three centuries later. The fourteenth-century choir stalls at Ely, 'among the finest which survive', must also be Hurley's work. Literature: Salzman (1952); Harvey (1984); Maddison (2000); Beech (2015).

|

|---|

| Imberhorne Farm Cottages: | An interesting group of buildings in East Grinstead, Sussex, which contain a medieval manor house.

The roof carpentry of the hall, tree-ring dated to 1428, is significant because it is one of the few hammer-beam roofs where the carpenter, at least superficially,

tried to emulate the design of Westminster Hall.

Literature: Clarke, Vernacular Architecture 36 (2005).

|

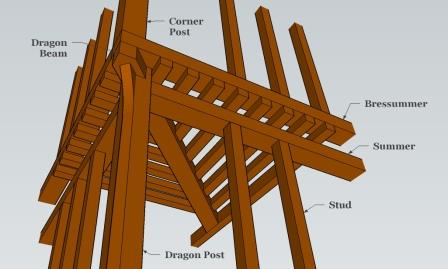

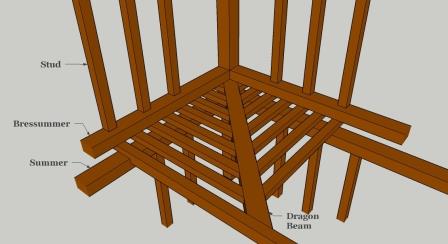

|---|---|

| Jetty: | The projection of wall or gable framing over a lower storey; the framing is generally accomplished by an extension of the joists, upon which is placed a bressummer or sill. A contract for the building of a shop in 1405 stipulates that the first floor 'shall jut' (lat. Gettabit). Is this the Latin etymon of the term? Contemporaries suspected the stability of jettied construction. The schoolmaster William Horman commented: ‘Buyldynge chargydde with iotyes (jetties) is parellous when it is very olde’, Vulgaria 1519).

Literature: Salzman, (1952).

|

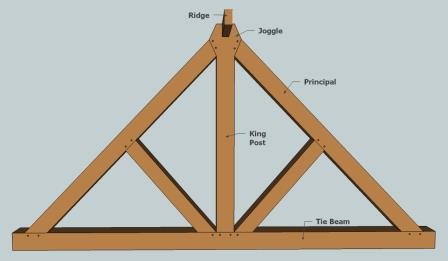

| Joggle: | Enlarged and faceted section at the top of a king post / strut to provide a more secure abutment for the principals against a king post designed to be in tension. See 'king-post truss' below. |

|---|---|

| Joist: | Timber carrying a floor or ceiling. |

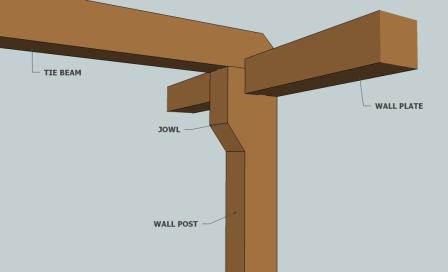

| Jowl: | The enlarged head or foot of a post, cut to accommodate more complex and secure framing than would be permitted by a post's general sectional dimensions. The jowl can take various forms, from gracefully flared, to square-cut. See illustration below and 'English Tying Joint' above. |

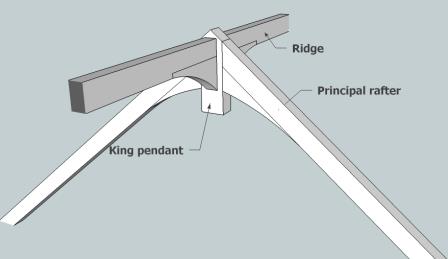

| King Pendant: | Generally, vertical timber at the apex of a principal roof-frame, into which are framed principal rafters and ridge. The pendant provides a timber to which the principals and ridge may be arch-braced, so providing structural and ornamental advantages at the apex. The pendant itself provides a location for ornament. King pendants are often found in fifteenth-century East Anglian church roofs.

See illustrations below.

Also, a similar component found in scissor-braced roof-frames.

Literature: Beech (2014; 2015).

|

|---|

Carbrooke Church, Norfolk, nave roof, fifteenth-century.

| King-Post Truss: | Roof truss. Main components are: principal rafters, tie beam and king post. Throughout the later middle ages, most English carpenters thought of the king post as a compression member, as indicated by the common practice of including heavy, cambered tie beams. Some carpenters, however, perhaps influenced by their continental counterparts and their use of 'hanger' tie beams in the great cathedral roofs, clearly came to think of the king post as a tension member. In this case, the tie beam is suspended from the king post, and the principals serve as props to the king post. Hence the use of joggles, dovetailed lap joints from king post to tie beam and, later, iron strapping. Pedantically, a king-post truss must carry a ridge (cf. 'King-strut truss' below). See illustration below. Literature: Harris (2006); Hoffsummer (2009); Yeomans (2009).

|

|---|

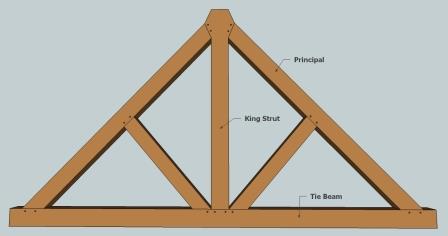

| King-Strut Truss: | One for the taxonomical purists. Similar to a king-post roof, but a king-strut roof has no ridge. |

|---|

| Lambeth Palace Guard Room: | The space now modestly dubbed the 'Guard Room' in Lambeth Palace was once the great hall of the Archbishop of Canterbury’s main London residence. Oddly under-researched, the timber roof therein is one of the finest examples of English medieval display carpentry. |

|---|

|

A series of transverse Gothic ribs dominates the vista. Of heavy section and deeply cut mouldings, these appear to sustain the roof. The eye, though, has been tricked, and scrutiny of the abstruse carpentry reveals the hall’s true construction, that of a more prosaic base cruck. The function of the timber ribs, then, is more visual than structural.

Tantalizingly, dating probably to the late fourteenth century, the roof may have been carpentered by Hugh Herland. It is certainly adorned with foil and dagger motifs similar to the King's Carpenter's work at Westminster Hall and the Abbots' Hall nearby. The tracery between cruck and arch brace is very similar to that at Westminster Hall between lower curved strut and arch rib. The difference lies mainly in a single foil: at Westminster a trefoil replaces Lambeth's quatrefoil. The roof also reflects Herland’s penchant for structural artifice. John Harvey noted further similarities to Westminster. He wrote that in the Lambeth roof 'the inner arch [brace] and outer curved strut [he means the cruck] follow almost the same lines as [at Westminster] the lower curved strut and the lower portion of the great arch rib … while the half span [at Lambeth] of 14ft (4.27m) is equal to [at Westminster] the distance from the wall surface to the point where the lower curved strut intersects the [soffit] of the hammer beam.' That probably takes a visit to the two structures (or an incredible talent for visualization!) to understand, but an intriguing possibility is that Herland at Lambeth was exploring the arcs and tangents he would shortly attempt half a mile away in Westminster Hall. Earlier I said that the roof belonged probably to the late fourteenth-century, but no certain date has been established. If the roof were ever tree-ring dated, it might just confirm a late C14 date. If so, it would be an insight into Herland's mental processes immediately before he was ferried across the Thames to begin work at Westminster. The Guard Room may have been Herland's last formal and technical dress rehearsal for his masterpiece. Literature: Dollman & Jobbins (1861); RCHME London, Vol. II, West London (1924-30); Harvey (1938); Hewett (1980); Courtenay (1984); Beech (2015).

|

|

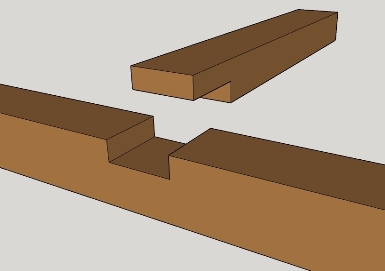

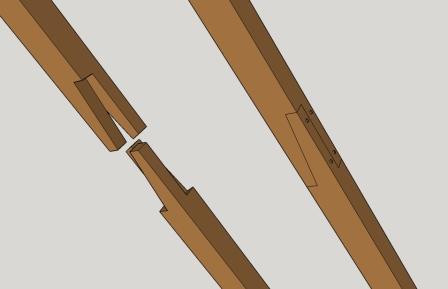

| Lap Joint: | A weaker, but more convenient, alternative to the mortice & tenon joint. Typically, the timber with the recess is of bigger section. Lap joints are often found on the braces and struts of extant late twelfth-century and thirteenth-century carpentry. Carpenters employed this joint not because they were incapable of chopping a mortice, but for reasons more to do with ease of erection (the 'tenons' do not need to be fitted into the four walls of a mortice) and an indifference to any aesthetic potential of carpentry. With the advent of 'display' carpentry in the fourteenth century, lap joints are less frequently found in structural timbers. The authorities disagree over the names of the various lap joints. At the risk of provoking a few hrrumphs I'll suggest the following: |

in the carpentry of the tower at Yarpole Church, Herefordshire.

This hugely important structure has been tree-ring dated to when Richard the Lionheart reigned, 1195-96.

For more examples of dovetailed lap joints see 'Lincoln Cathedral' below.

| Leigh Court Tithe Barn: | Awaiting entry |

|---|---|

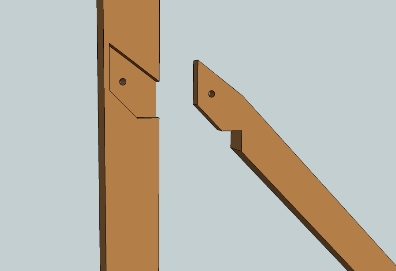

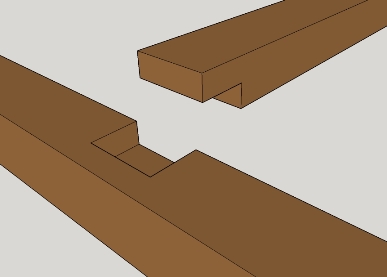

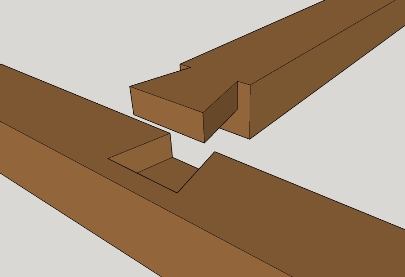

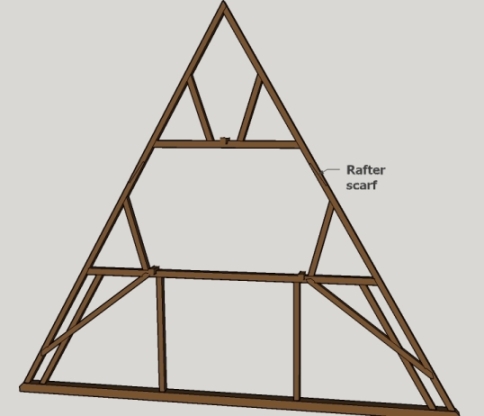

| Lincoln Cathedral: | Much of Lincoln Cathedral is sheltered by a wealth of original late twelfth and thirteenth-century carpentry. The roofs have been accurately dated, either by dendrochronology or contemporary documents, and dates for the major parts of the cathedral are:

St Hugh's Choir (the existing choir): 1192-1200 North-east & south-east transepts: 1192-1250 Nave: 1200-50 Angel Choir (the easternmost part of the cathedral): 1275-80 The carpentry in all these roofs is a variation on the theme established in one of the earliest, that over St Hugh’s Choir. The frame is an equilateral triangle, with a width of around 47ft (14.3m), and a clear span of around 42ft (12.8m). A typical frame is shown below: |

| We can see then in the Lincoln roofs the dynamics of the design process, how – what shall we say, three generations? - of carpenters

tweaked and revised the carpentry of these enormous roofs to improve their structural performance. Thus, the later Angel Choir roof, albeit with only minor modifications to the design over St Hugh's choir, is the most sophisticated – the carpenter evidently learning from and refining modifications in the earlier roofs.

These roofs are high and steeply pitched, so throughout carpenters were concerned with managing lateral wind forces. Indeed, the pitch over the south-east transept is an astonishing 70 deg. (In an unscientific perusal of books on continental carpentry, the steepest pitch I could find was in the roof over the nave of Reims Cathedral at a pitch of a mere 65 deg.) So at Lincoln carpenters experimented with varieties of strutting to get some compressive triangulation into their roofs to resist what must at times have been enormous dynamics. The experiments are evident: as decades progress we see timbers added, then removed, only to reappear again later. Puzzling, in their quest to manage lateral wind forces, is how the Lincoln carpenters generally eschewed scissor bracing, even though the technique was in use in both contemporary English and continental high roofs (Westminster Abbey, n. transept; Bayeux Cathedral, n. transept). It was not that the Lincoln carpenters were ignorant of the technique: they used it in the two inner bays of the north-east transept. But that’s it, and everywhere else they persevered with their simply strutted rafters and collars. Perhaps timber supply problems were the issue. Sagging tie-beams beams were also a worry for these carpenters, and again we see experimentation and adaption. Evidently the simple pegged tenon on the queen post (more precisely a 'queen strut') of the St Hugh's roof was pulling out, so later carpenters experimented. In the nave they cut a bare-faced lapped dovetail, and we see the experiment’s culmination in the full dovetail in the west end of the Angel Choir. |

| Carpenters must have been realizing that these queen posts, rather than standing in compression on a supportive tie-beam, were in

tension. If so, then their knowledge was not disseminated. While thirteenth-century French carpenters were grasping the tensional nature of such vertical roof timbers and were framing hanger king and queen posts, 'suspentes', in their great cathedral roofs (Paris, Notre Dame; Rouen Cathedral), throughout the Middle Ages English carpenters seemed to consider such timbers as compression members, and for centuries the potential of the king-post truss went unrealized.

The St Hugh's roof displays a resourceful craftsman with a repertoire of sophisticated jointing techniques. This is the 1190s, yet the framing features mortice & tenon joints, cogged joints, lap joints, notched lap joints and scarf joints. Most impressive is the scarf he cut to make up the full length of the rafters: the 'scissor-splayed-stopped-joint' with (according to drawings) under-squinted abutments (best just to look at the illustration below …) – a joint of ingenious conception, challenging to lay out and time-consuming to cut. |

|

Literature: The prose is not the most digestible, but the definitive source for the Lincoln roofs is Foot et al (1986). My drawings are based on those in that article. See also Hewett (1980 & 1985). For continental roofs See Hoffsummer (2009) and Epaud (2007).

|